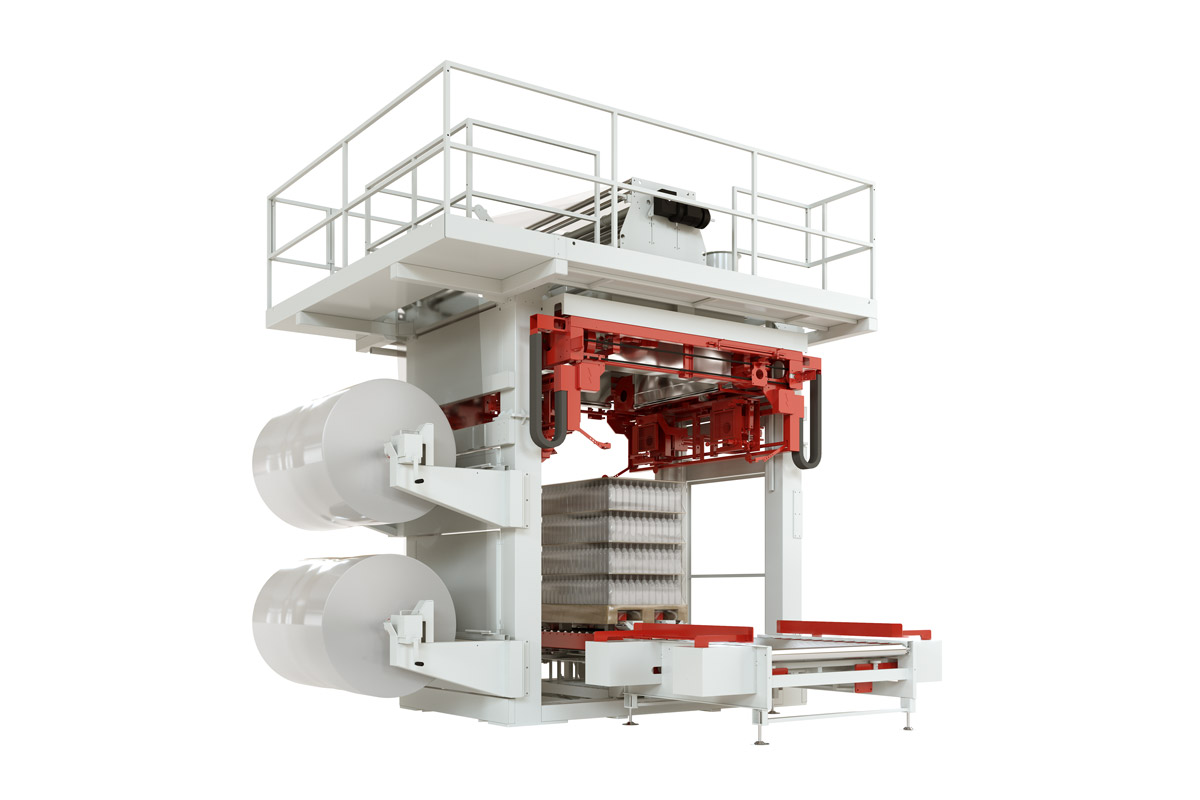

Shrink hooding technology

Shrink hooding is a consolidated packaging technology. Here in Bocedi we have over 50 years of experience of doing it.

It is a firm protection which combines the load to the pallet to guarantee stability during transport and storage and to protect your goods form dust and moisture.

Suitable for any load shape or pallet size

Shrink hood packaging technology is suitable for any load shape or pallet size, and it is specifically recommended for insulation materials like bitumen membranes and glass products, the shrinking hooding system does in fact apply the plastic shrinking hood without getting into contact with the product, and no pressing forces touch or alter the load shape.

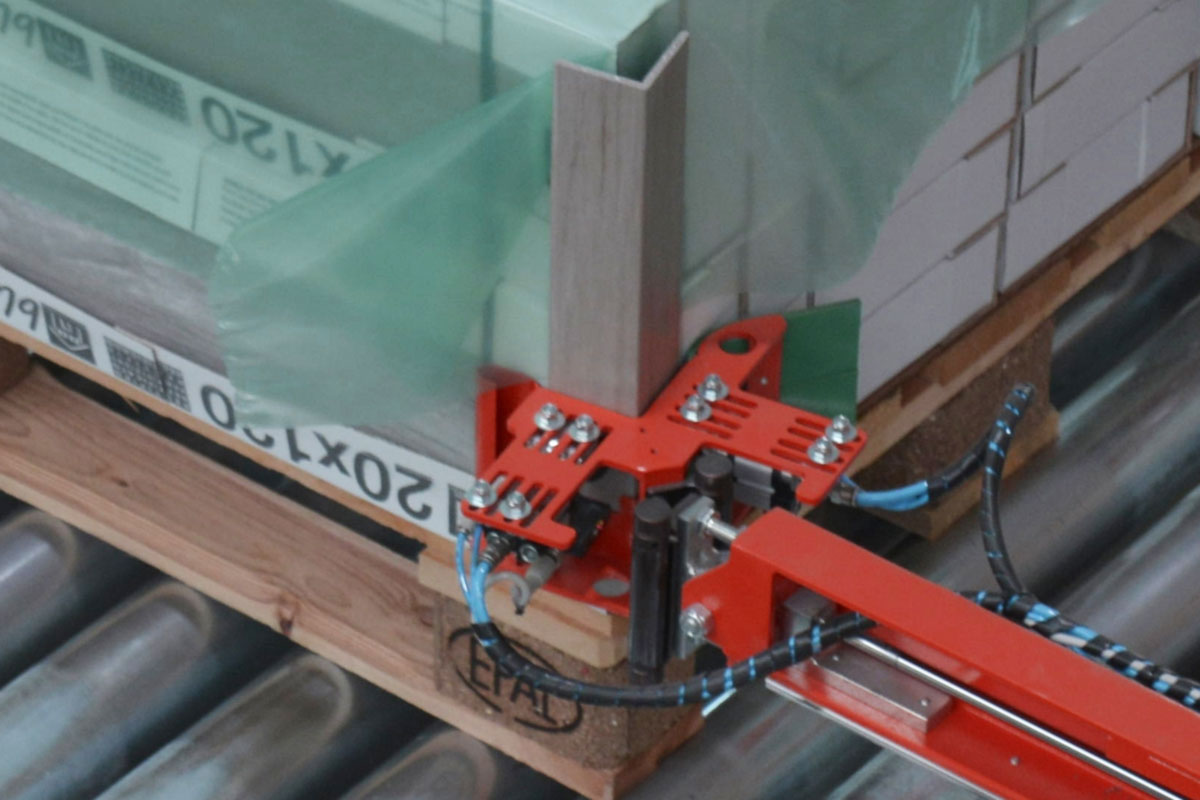

The shrink hood is unrolled from a thermo tubular film, automatically cut to measure by a sealing bar and then blown up like a balloon to avoid load contact while applying around the load.

Safe and stable

The Bocedi shrinking process starts from the bottom of the pallet ending at the top of the load while the air contained inside the hood is sucked up by an aspiration device. This method will ensure that the film is safely secured underneath the pallet granting excellent load stability.

Tailored shrinking rings use controlled hot air to evenly and gently heat up the plastic around the load; no direct contact with flames does in fact preserve the film elasticity and resistance.

Eco-friendly

The environment is always important; this is why Bocedi machines are designed to use as little film as possible and consume less energy and gas with the controller recycled hot air shrinking rings.

Recap

– Load stability

– Dirt, shock & sun with UV stabilization protection

– Customizable films for great branding

– High temperatures & puncture resistance

– Cost saving through less plastic with tailored – hood on each load

– Easy film handling

– High packaging performance